SLS-Selective Laser Sintering

The Introduction Of SLA 3D Printing

SLS Printing uses selective CO₂ laser sintering technology which sinters plastic powders (ceramic or metal powders with binding agent) into solid cross-sections layer by layer until a three-dimensional part is built.

Selective Laser Sintering (SLS) technology was invented by C.R. Decherd of the University of Texas at Austin.It is one of the 3D printing technologies with the most complex forming principles, the highest conditions, and the highest cost of equipment and material. However, it is still the most far-reaching technology to the development of 3D printing technology.

This is how it completes model production. The powder material is sintered layer by layer at high temperature under laser irradiation, and the computer controls the light source positioning device to achieve precise positioning. By repeating the process of laying out powder and melting where needed, the parts are built up in the powder bed

Advantages

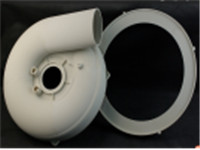

1. Simple manufacturing process: This process can directly produce prototypes, parts and tools of complex shapes according to different materials.

2. No extra support: SLS does not need a support structure, and the suspended layer that appears during the stacking process can be directly supported by the unsintered powder.

3. High material utilization rate: Because there is no need to support and add a base, it has the highest material utilization rate among several common 3D printing technologies.

4. Excellent mechanical properties: SLS technology uses polymer plastics such as nylon, so the printed parts usually have good mechanical properties, temperature resistance and chemical resistance. In addition to research and development testing purposes, they can also be directly used in final products, adding SLS technology to customers.

5. High molding efficiency. Since SLS technology does not completely melt the powder, but only sinters it, the manufacturing speed is fast.

Disadvantages

1. High equipment costs and maintenance costs: Due to the use of high-power lasers, own equipment, a lot of auxiliary protection process and the overall technical difficulty, manufacturing and maintenance costs are quietly high.

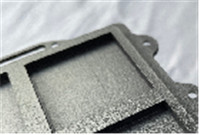

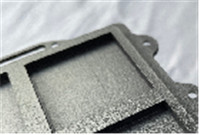

2. Surface quality is not high: Strictly speaking, the surface of the prototype is powdery, so it can not meet the requirements of customers who pursue high-quality surfaces.

3. Not environmental protection: Polymer materials or powders will volatilize odorous gas during laser sintering.

Application Areas

1. Process standard plastic with functional prototypes.

2. Support parts, such as jigs, fixtures and other customized products.

3. Small batch production.

Industries with SLS 3D Printing

SLS Materials

SLS materials are quite extensive. Theoretically, any powder material that can form interatomic bonding after heating can be used as SLS molding material, such as polymers, metals, ceramics, gypsum, nylon, etc. However, 90% of the materials used in SLS on the market are nylon, so people usually think that nylon is the material of SLS. Commonly used nylon materials are PA12 and PA12+GF.

SLA Materials

| PA12 | Domestic nylon | Technology: SLS Precision build: 0.12mm layer thickness |

|

Gray | Strong toughness/hardness |

|

White | ||||

| HP Nylon | Technology: SLS Precision build: 0.08mm layer thickness |

|

Gray | Durable, low production cost | |

| PA12+GF | HP Nylon |  |

Gray | High hardness and stable size |

Post Processing

Nylon printed models are only available in gray and white, and we can dip-dye them into different colors according to customers’ needs.