MJF-Multi Jet Fusion

The Introduction Of MJF 3D Printing

MJF 3D printing process is one of the 3D printing processes just emerged in recent years, mainly developed by HP. It is known as a major “backbone” of emerging additive manufacturing technology.

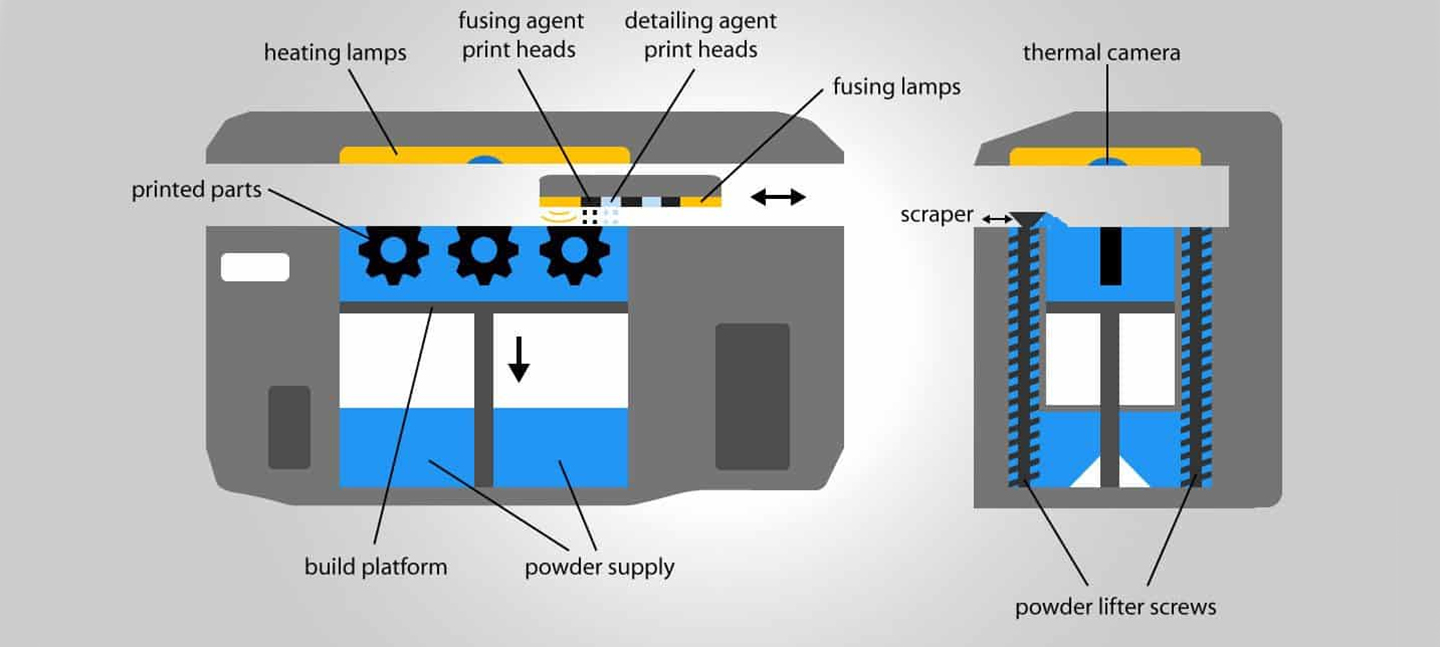

The principle of MJF process works as follows: at first, the “powdering module” moves up and down to lay a layer of uniform powder. The “hot nozzle module” then moves from side to side to spray the two reagents, while heating and melting the material in the print area through heat sources on both sides. The process repeats until the final print is complete.

Advantages

1. Theoretically, the printing speed is 10 times that of SLS or FDM

2. Streamline workflow and reduce costs

3. Printed parts with good mechanical properties make functional verification possible

4. The material reuse rate can reach 80%, reducing the production cost of users

5. The finished product can be printed directly according to customer needs

Disadvantages

Material limitation: the available material is only black nylon 12 (PA12), and more available materials depend on HP’s development of fine agents;

Application areas:

1. Process standard plastic with functional prototypes.

2. Support parts, such as jigs, fixtures and other customized products.

3. Small batch production.

MJF Materials

Only black PA12

Industries with SLS 3D Printing

● Aerospace

● Household electronic

● Automobile

● Medical assistance

● Art and craft

● Architecture