SLM – Selective Laser Melting

Profile

SLM: Selective Laser Melting

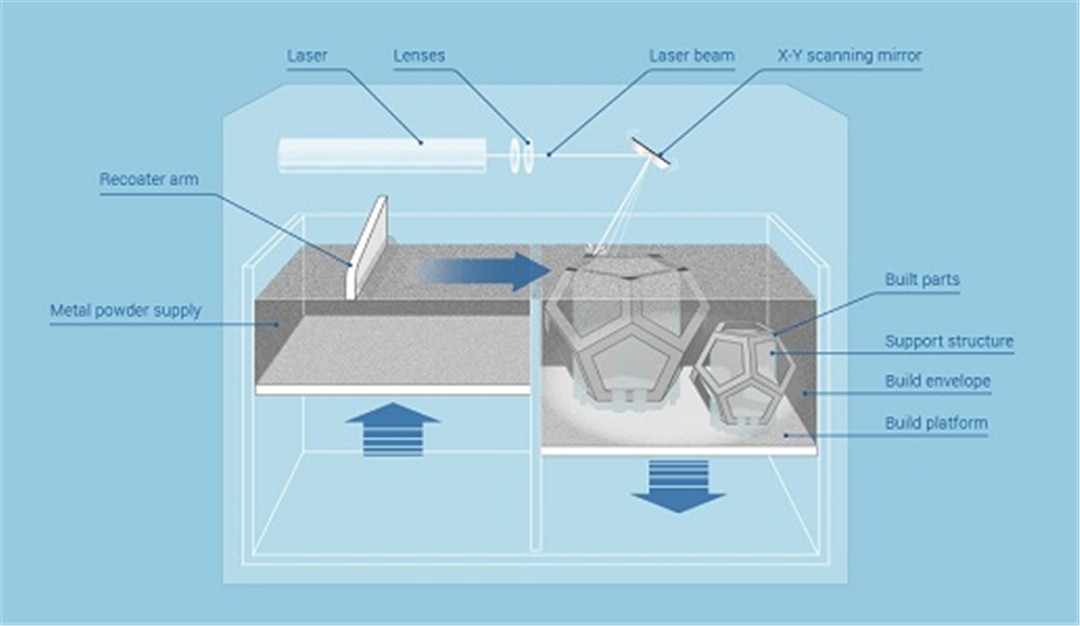

As the main technology in the additive manufacturing of metal materials, SLM selects laser as the energy source. During manufacturing, the laser scans the metal powder bed layer by layer according to the path set in the 3D CAD slice model. The metal powder scanned melts and solidifies. This process is repeated to finally get the metal parts designed.

SLM technology overcomes the difficulties caused by traditional technology, when manufacturing metal parts with complex shapes, and directly forms metal parts with nearly full density and good mechanical properties.

The principle of SLM 3D Printing

SLM is a technology in which metal powder is completely melted under the heat of a laser beam and then cooled and solidified.

It needs to add a support structure whose main functions are:

1. undertake the next layer of unformed powder layer, prevent the laser scanning of too thick metal powder layer and collapse;

2. After the powder is heated, melted and cooled during molding process, there is shrinkage stress inside, which may cause the parts to warp, etc. The support structure connects the formed part and the unformed part, which can effectively suppress this shrinkage and keep the stress balance of the formed part.

After completion, support on the model will be removed, and the surface is ground and polished with a sander. Then the model is completed.

Advantages

1. The density of standard metals processed by SLM process exceeds 99%, and the excellent mechanical properties are comparable to traditional processes

2. Directly design and manufacture metal functional parts with complex geometric shapes without intermediate processes

3. The types of materials being used continue to increase, and the processed parts can be welded later

4. Optimize product design, replace the original solid body with a complex and reasonable structure so that the weight of the finished product is lower, thereby reducing the overall cost.

Disadvantages

1 .Expensive equipment and materials.

2. Slow printing speed and long manufacturing time.

3. Rough model surface and relatively low accuracy.

Application Areas

Prototypes

Process standard metal with functional prototypes.

Customized Products

Support parts such as clamps, fixtures, etc and customization

Small Batched Products

SLM can be applied to make high-quality small batched products from 1-100 units

Industries with SLM 3D Printing

Aerospace; Automotive; Medical; Machinery manufacturing; Mould manufacturing; Architecture

SLA Materials

| Metal | Specification | Pictures | Color | Performance advantage | |

| SLM | Stainless Steel (316L) | Rapid manufacturing layer thickness: 0.05mm-0.15mm Precision manufacturing layer thickness: 0.02mm-0.05mm |

|

grey | High strength, good corrosion resistance |

| SLM | Aluminum | Rapid manufacturing layer thickness: 0.05mm-0.15mm Precision manufacturing layer thickness: 0.02mm-0.05mm |

|

grey | Low density, high strength |

| SLM | MS1 | Rapid manufacturing layer thickness: 0.05mm-0.15mm Precision manufacturing layer thickness: 0.02mm-0.05mm |

|

grey | Impact resistance, simple heat treatment and not easy to deform |

| SLM | TC4 | Rapid manufacturing layer thickness: 0.05mm-0.15mm Precision manufacturing layer thickness: 0.02mm-0.05mm |

|

gray | High strength and corrosion resistance |

Post Processing

| Painting | Matte |  |

Customized |

| Glossy |  |

Customized | |

| Plating | Electroplating |  |

Customized |

| Sputtering |  |

Customized | |

| Sanding | Ordinary |  |

|

| Fine |  |

Grey | |

| Silk Printing |  |

Customized |